Description

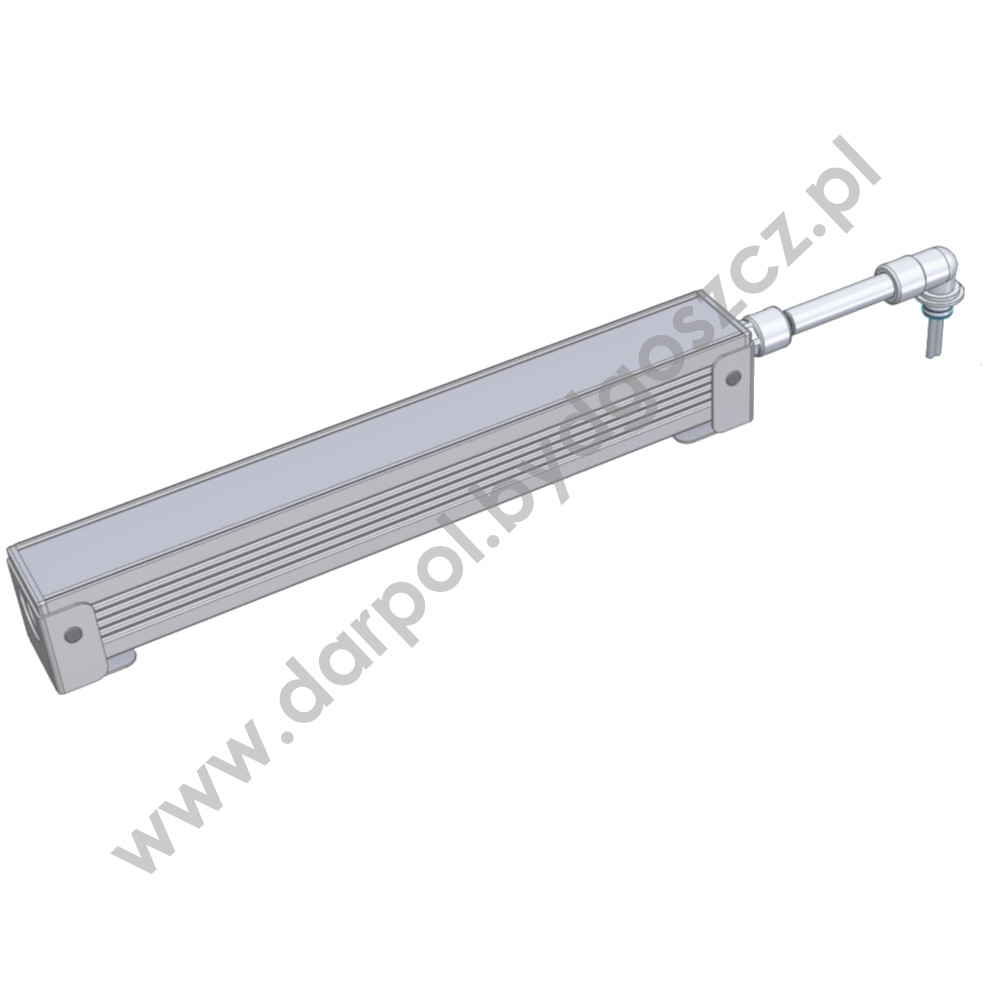

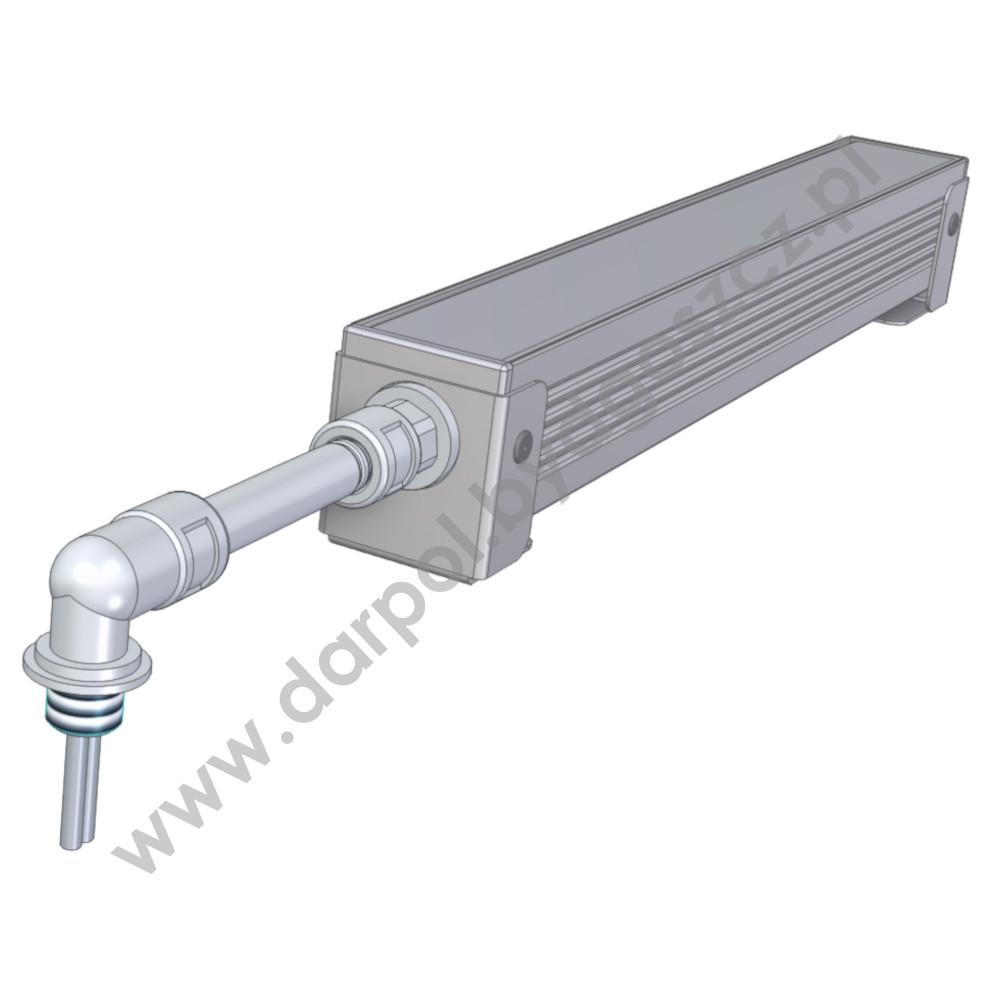

The DL-03-026-02 auxiliary chassis lighting lamp is designed to illuminate the undercarriage space of a rail vehicle.

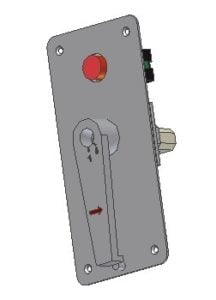

The lamp is, in principle, a maintenance-free component. It comes down to switching the lamp on or off to illuminate the elements intended for this purpose.

The introduction of the auxiliary chassis lighting lamp for rolling stock significantly improves the safety, efficiency and quality of service, which in the long term translates into savings and better operation of the entire transport system.

Benefits:

1. Improved work safety

+ Better visibility: Undercarriage lighting allows employees to more accurately assess the technical condition of structural elements, eliminating the risk of failures not being noticed.

+ Reducing the risk of accidents: Working in an appropriately lit environment reduces the possibility of trips, falls or other dangerous situations during inspections or repairs.

2. Facilitating diagnostics and maintenance

+ Quick detection of faults: Bright light allows for more accurate and faster detection of possible damage, leaks or wear of parts.

+ More accurate technical inspections: Thanks to the lamps, the condition of components can be better analyzed, which supports diagnostic processes and minimizes the risk of errors.

3. Increased operational efficiency

+ Accelerated service work: Lighting allows for faster and more accurate performance of maintenance or repair activities, saving time and resources.

+ Better accessibility in difficult conditions: Even at night or in dark halls, employees can perform their tasks effectively.

4. Longer service life of rolling stock

+ Prevention of damage: Regular inspections in a well-lit environment help identify problems before they develop into more serious failures.

+ More accurate maintenance: Lighting supports precision in servicing, which translates into better functioning and longer service life of equipment.

5. Work comfort for personnel

+ Reduced visual strain: Employees do not have to use hand-held flashlights or other light sources, which improves work ergonomics.

+ Better quality of work: Comfortable lighting conditions increase employee accuracy and efficiency.

6. Increased compliance with standards and regulations

+ Meeting health and safety requirements: Adequate lighting is often a regulatory requirement in industrial facilities and service work.

+ Compliance with technical standards: The introduction of professional lighting supports compliance with industry standards.

Technical data:

Material: Aluminum, Stainless steel, Polycarbonate

Finish: powder coating (customer requirements can be customized)

Power supply: 24 VDC +25% – 30%

Operating temperature: -20/+45°C

Light temperature: 4000K

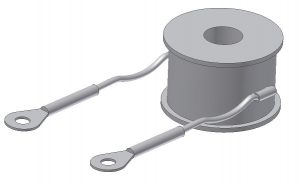

Length of power cables: ~3m

Length: 288 mm (314mm with gland)

Width: 37 mm

Height: 44 mm

Weight: 0.5 kg

Application: locomotives, EMUs, DMUs